Today I released the Arduino Ethernet Library version 2.0.0, for all Arduino boards (not just Teensy).

Version 2.0.0 adds many new features and greatly improves performance. Here’s a detailed look at what’s new.

Auto-Detect Hardware

All 3 SPI-based chips from Wiznet, W5100, W5200, and W5500 are supported. Ethernet.begin() automatically detects which chip you have connected.

The chip detection process uses the Wiznet software reset command followed by 2 write and read-to-verify checks on the main configuration register, for very robust hardware detection.

Ethernet.init(cspin), an extension added in Adafruit’s Ethernet2 library, is also supported, so you can use any digital pin for the CS signal.

Performance Improvement

Version 2.0.0 greatly improves performance. Optimizations at multiple levels within the library work together to vastly improve performance, especially on the oldest W5100 hardware, and also make the most of the newer W5200 and W5500 chips.

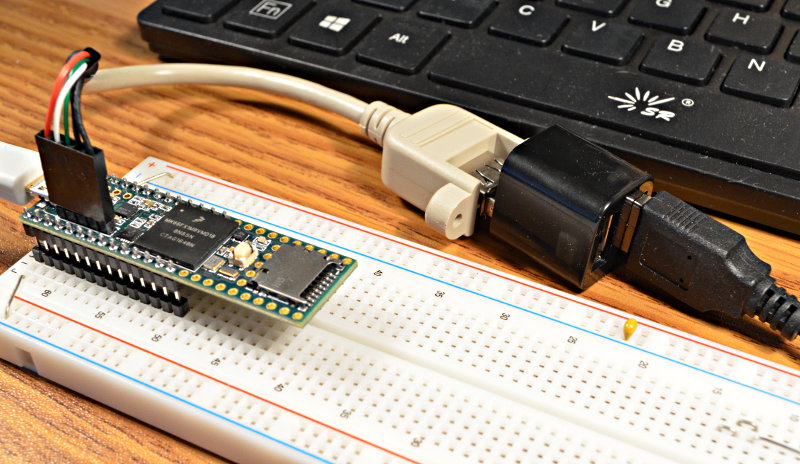

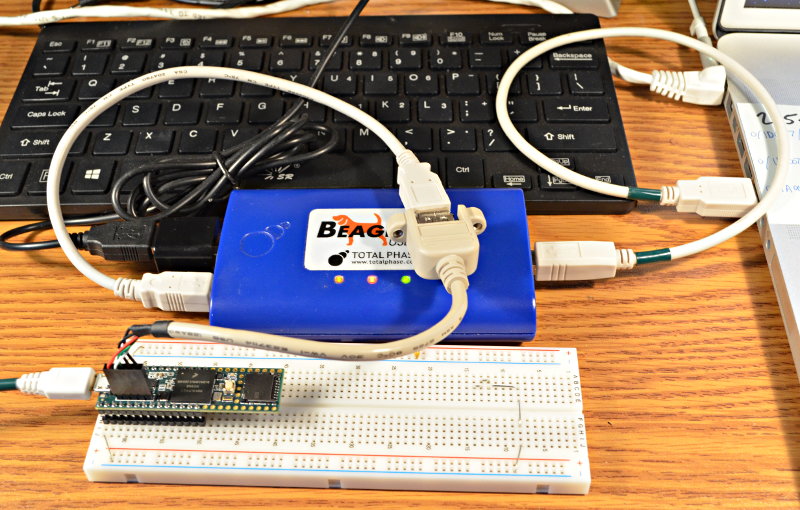

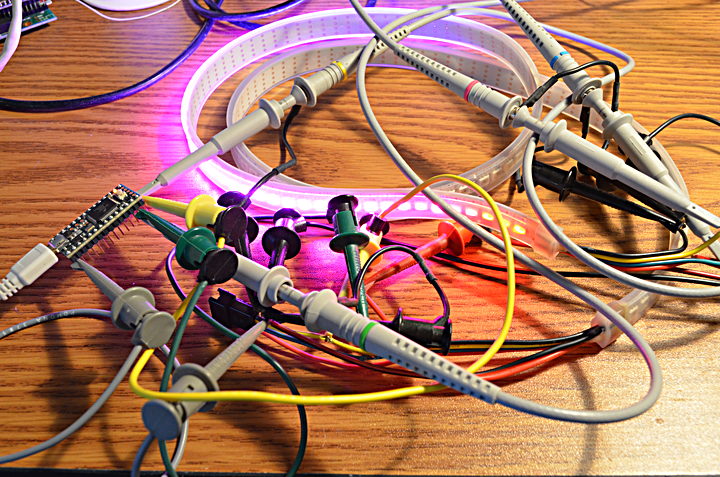

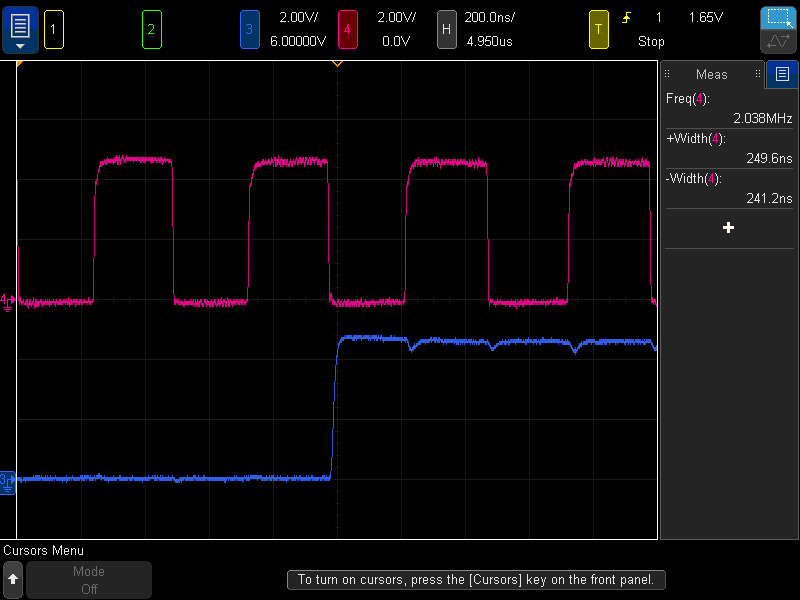

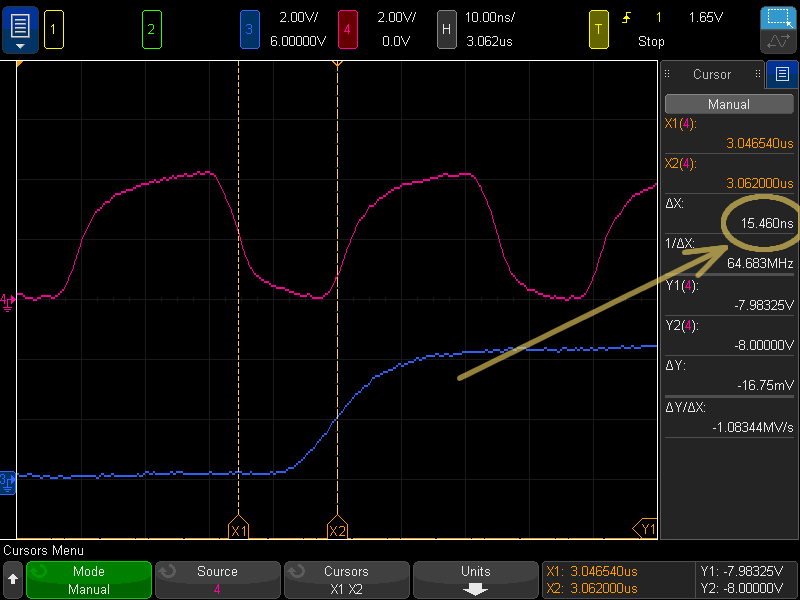

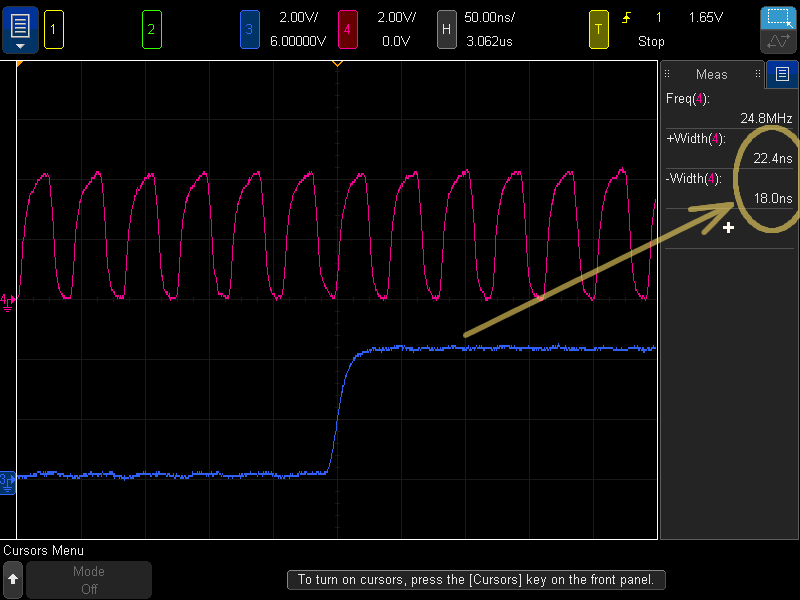

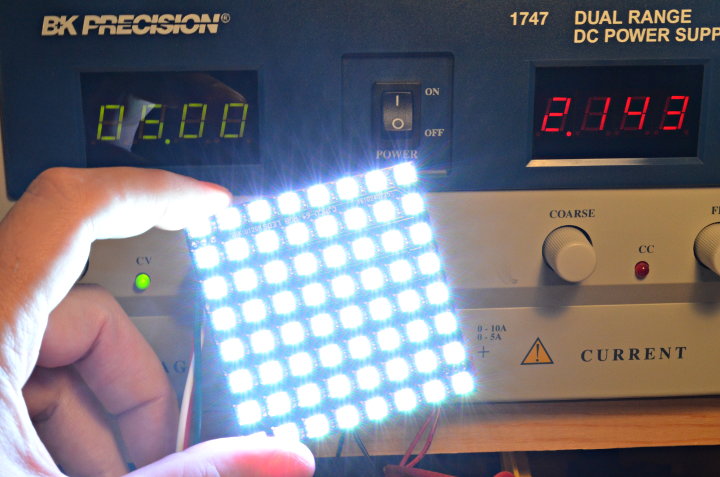

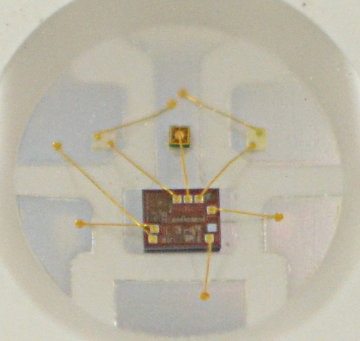

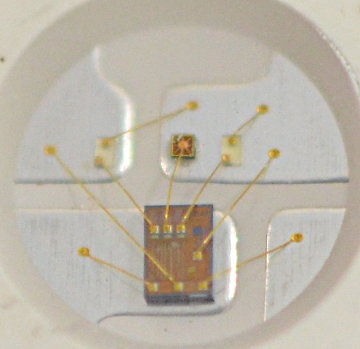

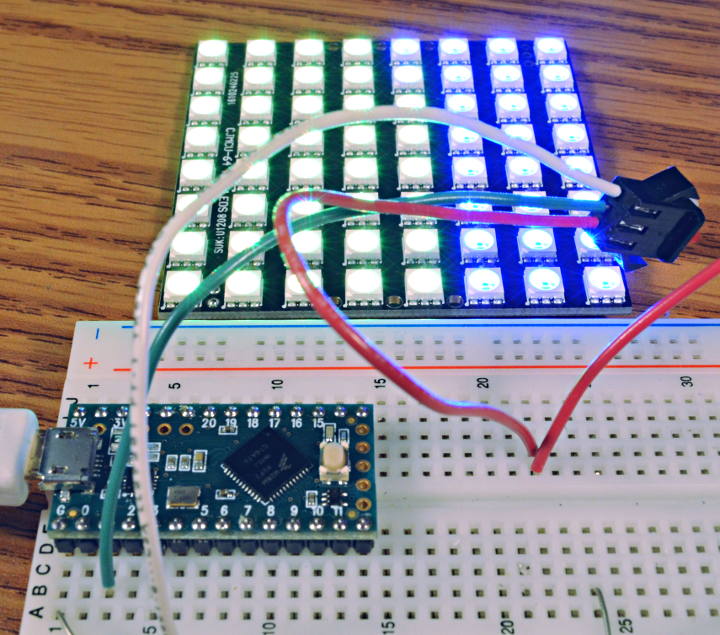

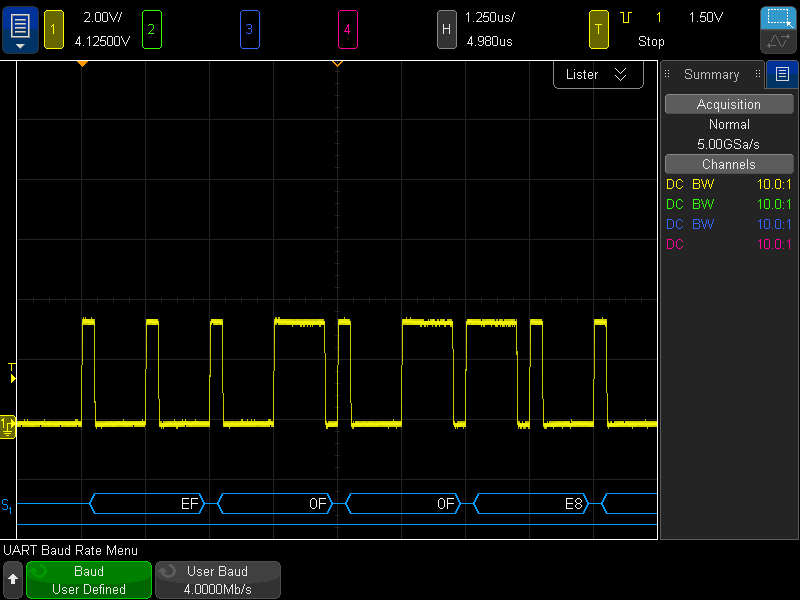

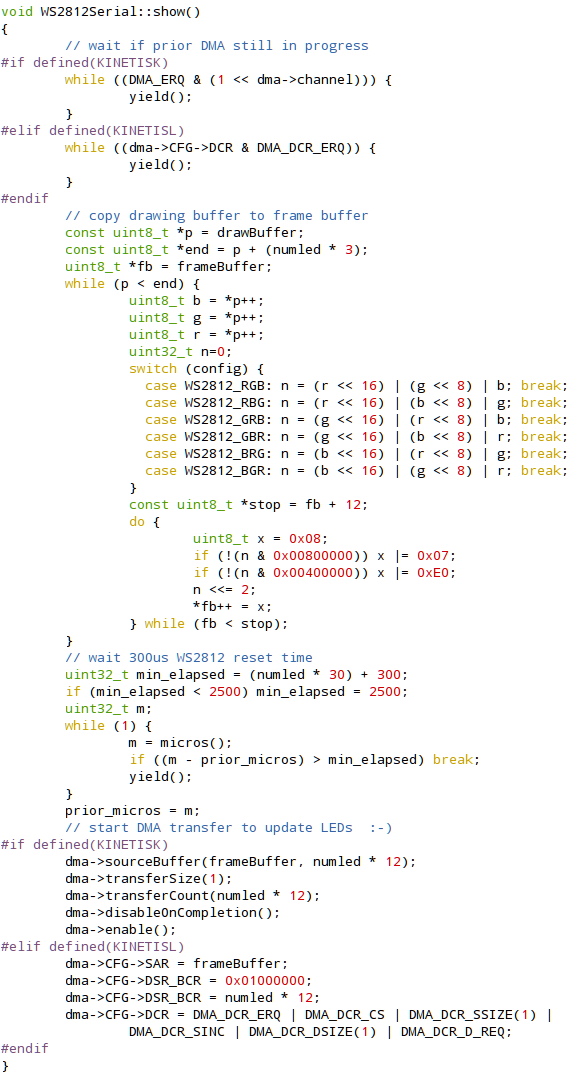

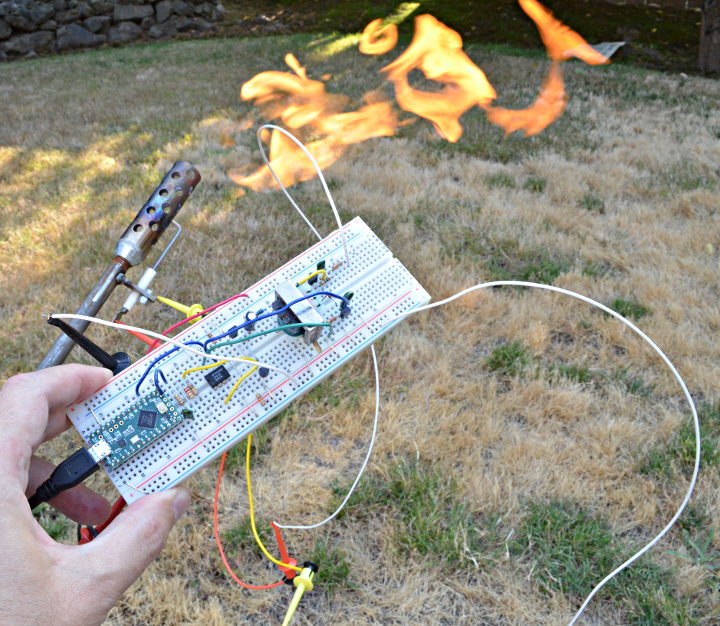

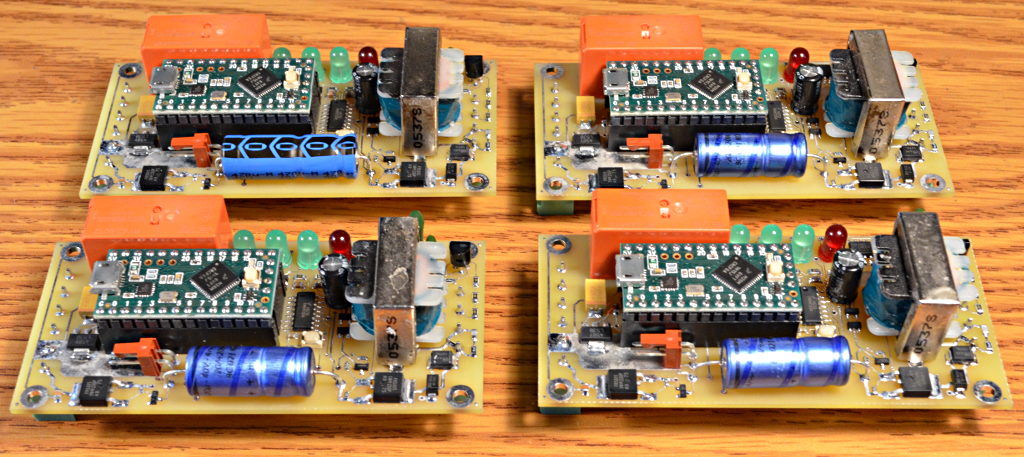

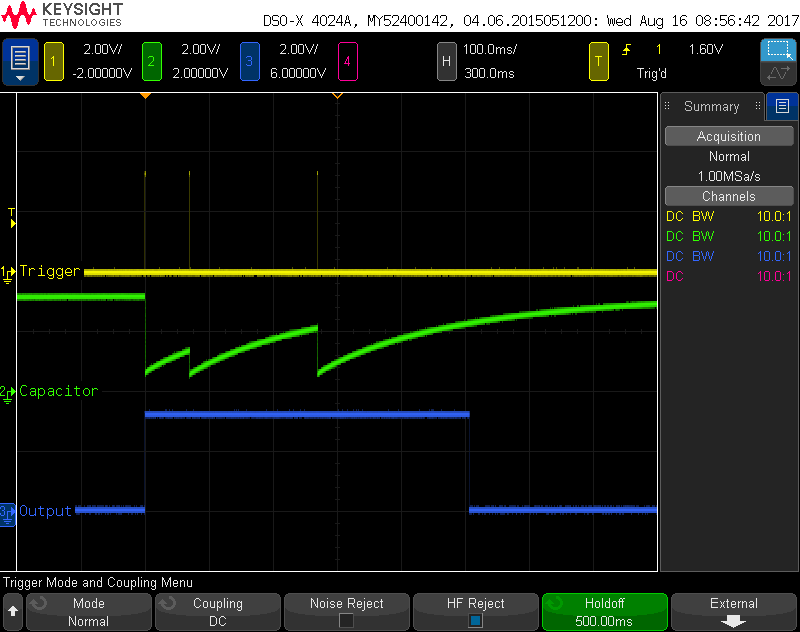

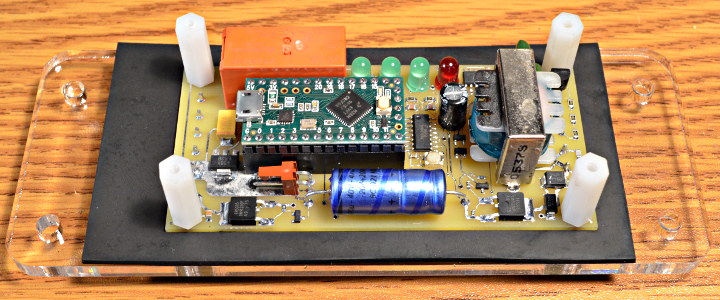

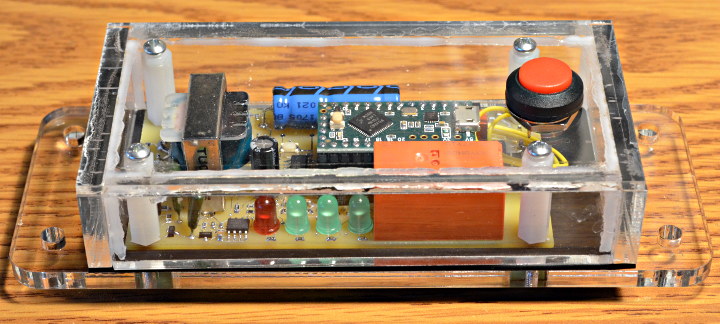

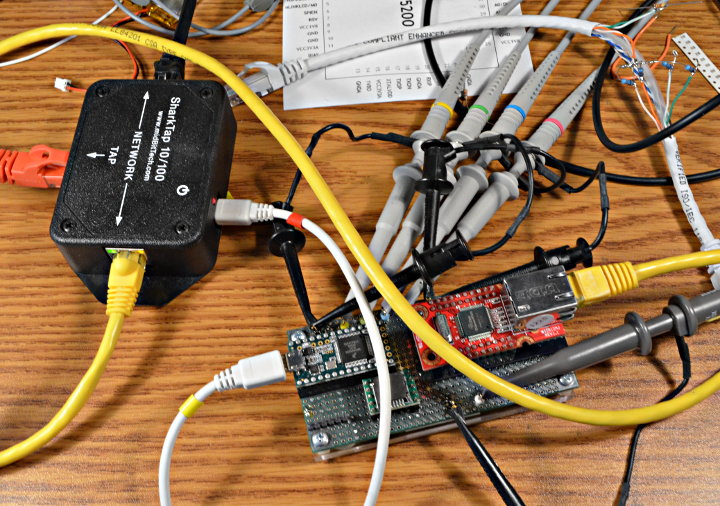

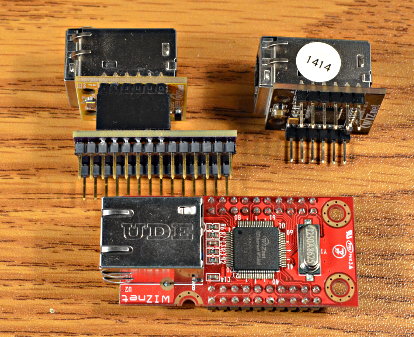

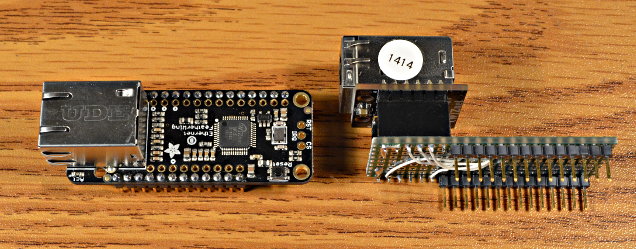

A a tremendous amount of work went into these optimizations. In this photo you can see the setup for debugging timing issues with WIZ812MJ (W5100) and Teensy 3.2, using a 4 channel oscilloscope to monitor SPI communication and an active network tap to monitor the Ethernet packets.

The 2.0.0 performance optimizations are performed on 6 levels. Here are details, from the highest to the lowest level.

1: Caching Socket Registers

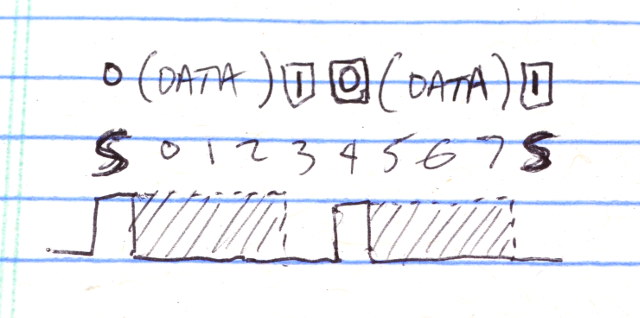

The Wiznet chips transmit and receive Ethernet packets with their internal buffer memory. Each socket’s buffers are managed using several 16 bit pointer registers within the chip. Previously these registers would be read and sometimes updated for every access, using many bytes of SPI communication, even just to check whether data is available.

A small amount of memory on the Arduino side is used to cache these registers, which greatly reduces non-data SPI communication.

2: Immediate TCP ACK

By default the Wiznet chips have a feature to delay sending TCP ACK packets. For simple programs which read 1 byte at a time, this makes good sense, since you wouldn’t want to transmit a flood of ACK packets for every single received byte.

The socket register caching also allows the number of Sock_RECV commands written to the chip to be greatly reduced, even for simple Arduino sketches which read 1 byte at a time. This allows Ethernet 2.0.0 to control the timing of ACK packets, immediately when the Sock_RECV command is used to update the chip’s buffer pointers.

W5100 chips see a tremendous TCP speed boost, because the delayed ACK feature was poorly implemented in that old chip. Even W5200 & W5500 speed is improved, especially when larger buffers are used.

3: Block Mode For Data Transfer

All SPI commands have overhead, 3 bytes on W5100 & W5500, 4 bytes on W5200, before actually communicating data. On W5200 & W5500, after suffering this overhead, “block mode” allows many bytes can be transferred using a single command.

When your Arduino sketch reads or writes multiple bytes, these efficient block mode commands are used. Other libraries, like Adafruit & Seeed Studios Ethernet2 have used this block mode for data transfer.

4: Block Mode For Registers

Unlike other libraries for W5200 or W5500, the efficient block most is also used with accessing 16 and 32 bit registers. In addition to nearly cutting the register access time in half (and register access is done much less often due to caching), block mode also greatly reduces the chances that a register which may change will being read will need to be accessed more than twice to get the same value.

5: SPI Block Transfer

The SPI library has a block transfer function which is optimized to reduce delays between bytes on the SPI bus. W5200 & W5500 now leverage SPI.transfer(buffer, size) for a significant speed increase when used with boards having a SPI library which optimizes this function.

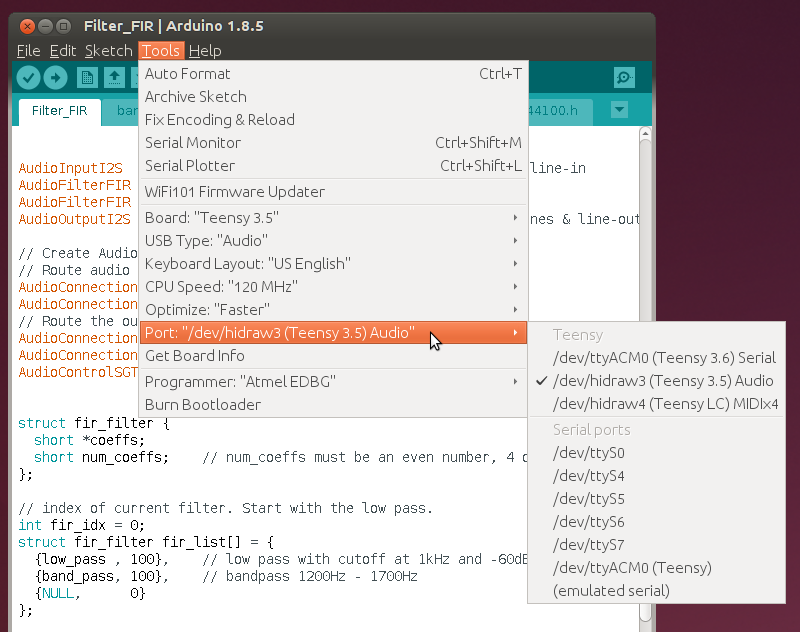

6: Native CS Pin Control

Control of the CS pin in version 1.1 was done using hard-coded register access to pin 10. While very efficient, only certain boards were supported and using any other pin required editing the library.

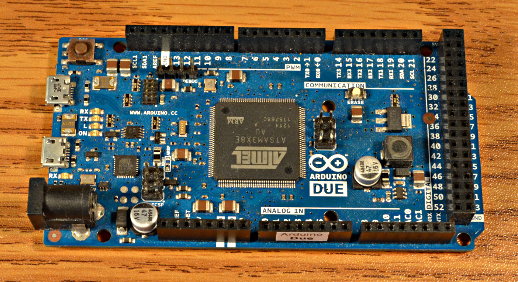

Version 2.0.0 allows any digital pin, but still uses efficient access to GPIO registers on most boards. All AVR, SAMD, SAM (Arduino Due), PIC32, Teensy and ESP32 boards are supported. On others, the CS pin control uses ordinary digitalWrite.

Client Functions

EthernetClient has 3 new functions similar to the ones from EthernetUDP. The remoteIP() function is very nice after connecting, if you used a name and DNS found the IP number.

remoteIP() localPort() remotePort()

Timeout Control

When things don’t go as expected, the default timeouts can be quite lengthy. Especially when communicating on with local devices on the same LAN, you might like much shorter timeouts.

Ethernet.setRetransmissionTimeout(milliseconds) Ethernet.setRetransmissionCount(number) client setConnectionTimeout(milliseconds)

The connection timeout is how long to wait when trying to connect to a server, or for stop() to wait for the remote host to disconnect.

Server Functions

EthernetServer now has an accept() function, for use by more advanced projects. The traditional available() function would only tell you of a new client after it sent data, which makes some protocols like FTP impossible to properly implement.

The intention is programs will use either available() or accept(), but not both. With available(), the client connection continues to be managed by EthernetServer. You don’t need to keep a client object, since calling available() will give you whatever client has sent data. Simple servers can be written with very little code using available().

With accept(), EthernetServer gives you the client only once, regardless of whether it has sent any data. You must keep track of the connected clients. This requires more code, but you gain more control.

EthernetServer now also has a boolean test, which tells you whether the server is listening for new clients. You can use this to detect whether EthernetServer begin() was successful. It can also tell you when no more sockets are available to listen for more clients, because the maximum number have connected.

Hardware Status

Version 2.0.0 adds two functions to help you diagnose hardware issues.

Ethernet.hardwareStatus() tells you which Wiznet chip was detected during Ethernet.begin(), if any. When “nothing works” this can help you discover whether your Ethernet shield hardware is good and you should check for networking issues, or if you need to work on the hardware first.

Ethernet.linkStatus() on W5200 and W5500 tells you whether the link is active. Sometimes things don’t work only because a cable is unplugged.

All the examples updated have been updated to use these, for better troubleshooting.

Direct Settings Control

Now you can access the network settings after Ethernet.begin(). These are meant to be used in manual configuration mode, not with DHCP.

Ethernet.setMACAddress() Ethernet.setLocalIP() Ethernet.setSubnetMask() Ethernet.setGatewayIP() Ethernet.setDnsServerIP() Ethernet.MACAddress() Ethernet.localIP() Ethernet.subnetMask() Ethernet.gatewayIP() Ethernet.dnsServerIP()

Boards Tested

I attempted to test Ethernet 2.0.0 with as many boards as possible.

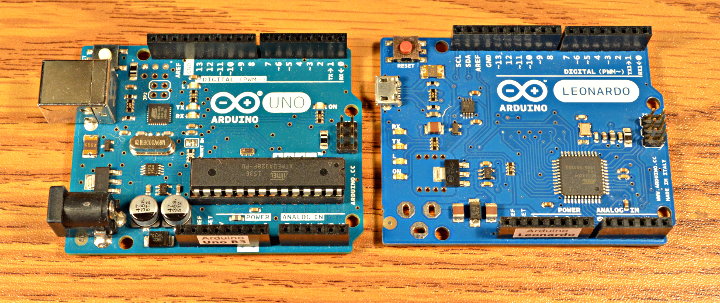

Arduino Uno R3 and Arduino Leonardo

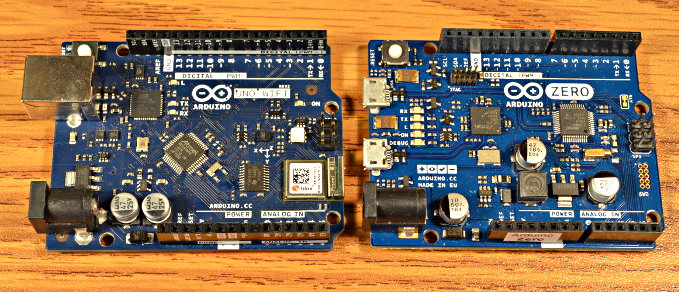

Arduino Uno Wifi Rev2 (pre-release sample) and Arduino Zero

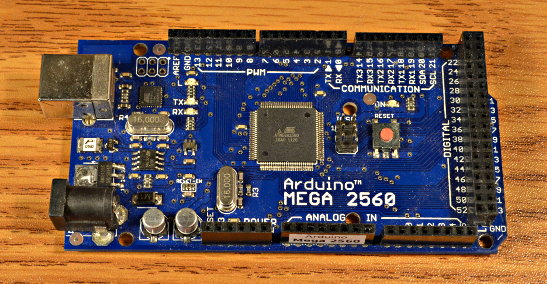

Arduino Mega 2560 (counterfeit/clone – sorry Massimo…)

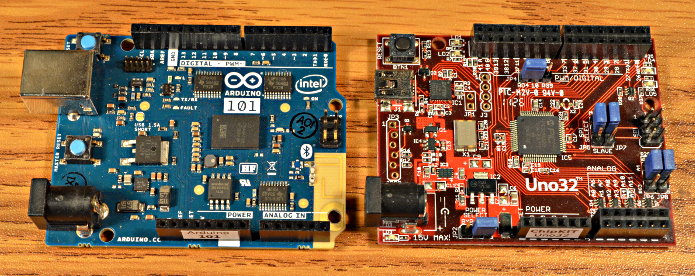

Arduino 101 Intel Curie and ChipKit Uno32

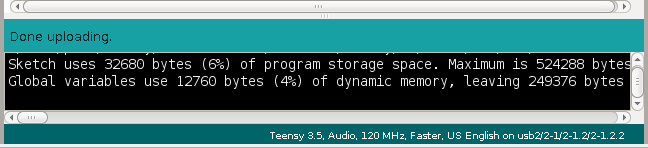

Teensy 2.0, Teensy LC, Teensy 3.2, and Teensy 3.6 Reference Board

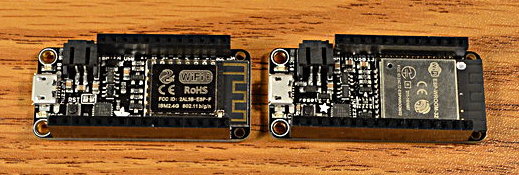

Adafruit Huzzah ESP8266 Feather and Huzzah32 ESP32 Feather

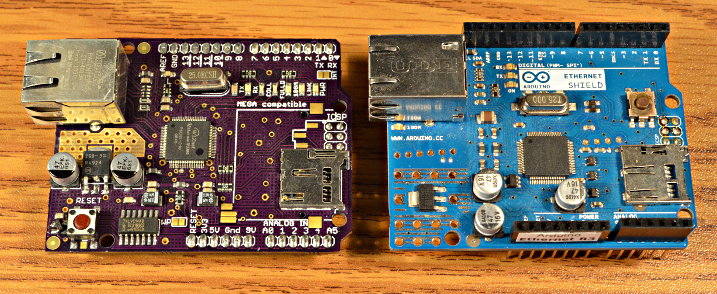

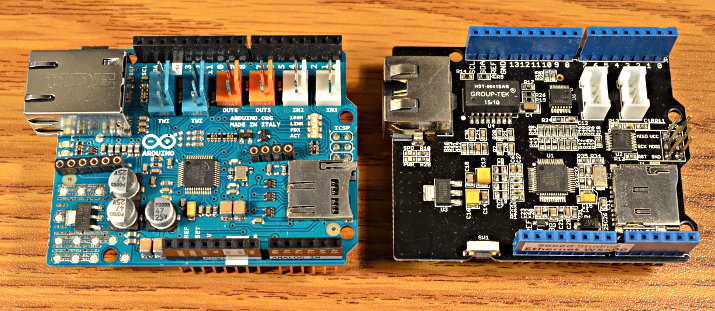

Shields Tested

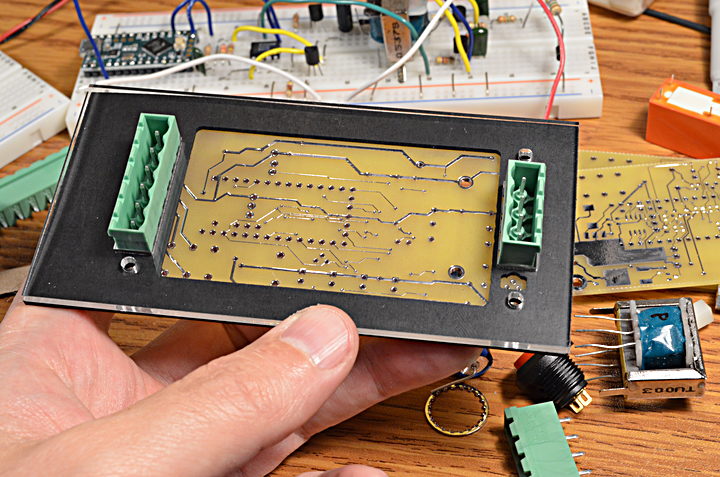

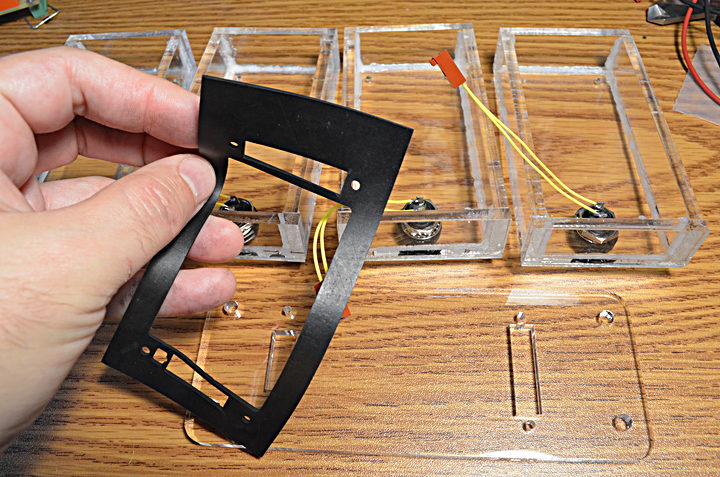

Arduino Ethernet R2 (hand soldered) and Arduino Ethernet R3

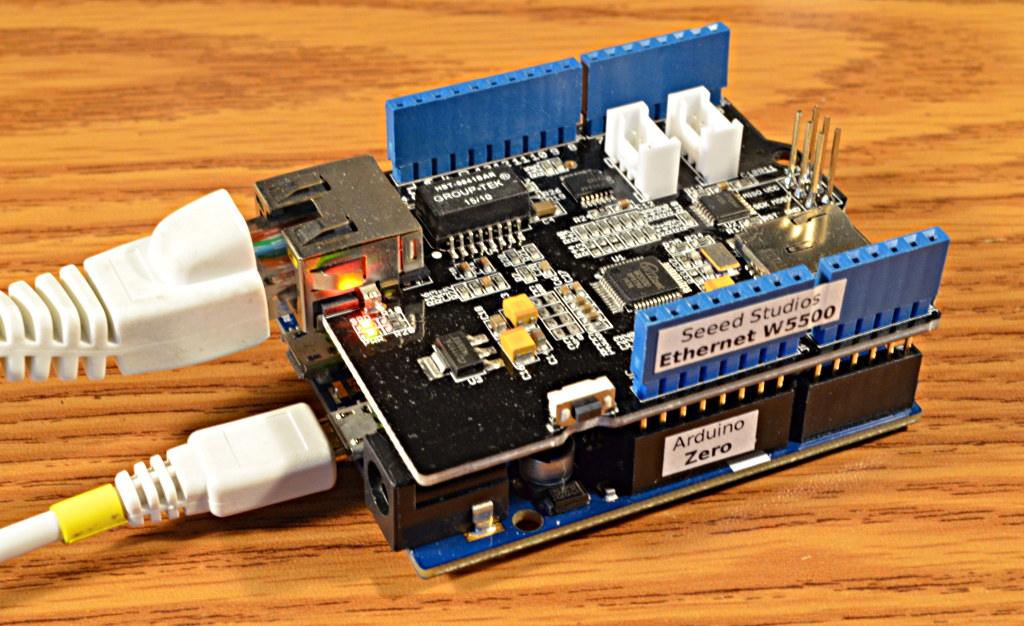

Arduino.org Ethernet2 and Seeed Studios W5500 Ethernet

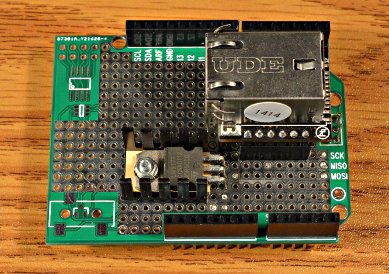

Wiznet WIZ820io on hand-soldered protoboard adaptor

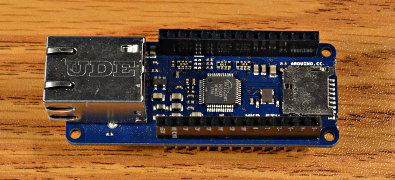

Arduino MRK ETH (pre-release sample)

Wiznet WIZ850io with Teensy adaptor, WIZ820io, and WIZ812MJ.

Adafruit FeatherWing Ethernet and WIZ820io with MKR adaptor

ESP8266 SPI library requires issue #2677 fixed – transfer(buffer, size)

ESP32 SPI library requires issue #1623 fixed – transfer(buffer, size)

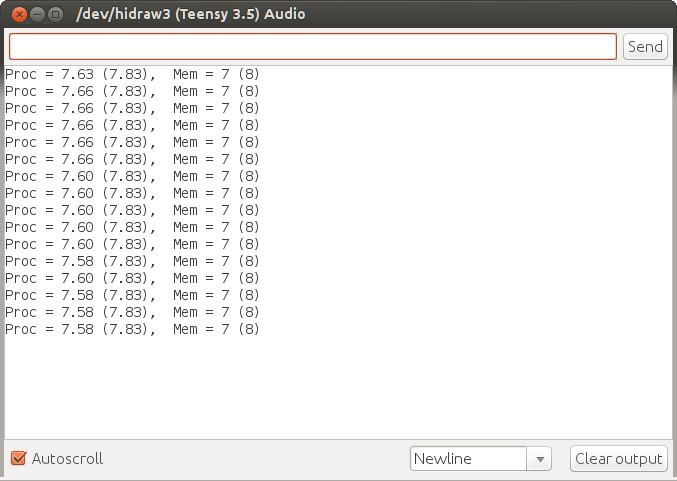

Benchmarks & Test Results

Four tests were run on every board+shield tested.

WebClient (local) is a copy of the WebClient example, modified to access a Linux web server on the same LAN, where packets have only the latency of a layer2 Ethernet switch, less than 0.1 ms. This test primarily measures the SPI communication speed and CPU overhead. Well optimized SPI library code greatly impacts this test. Numbers below are in kbytes/sec. If you care about LAN-connected speeds, and your hardware is capable of higher SPI clock speeds, editing w5100.h can greatly increase this performance.

WebClient (google) is the WebClient example without any changes. In this test, packets have approximately 7 ms latency. This test measures how well the TCP communication works with Internet latency. Numbers below are in kbytes/sec. These numbers vary considerably. The test was run 4 times on each board with the highest speed recorded. YMMV! If you care about Internet-connected speeds, editing Ethernet.h for fewer sockets and larger buffers can increase this performance.

UdpNtpClient tests UDP networking. This example was run and 3 responses from the NTP time server was considered passing the test.

WebServer tests the EthernetServer functionality. This example was run and a browser on a computer connected to the local network was used to access the analog readings info 3 times.

Board Shield WebClient WebClient UdpNtpClient WebServer

(local) (google)

-- larger numbers = faster data transfer --

Arduino Uno R3 Arduino Ethernet R2 82.66 79.27 ok ok

Arduino Ethernet R3 82.66 79.11 ok ok

WIZ820io 331.27 191.85 ok ok

Arduino.org Ethernet2 329.60 195.32 ok ok

Seeed Ethernet W5500 329.00 185.44 ok ok

Arduino Leonardo Arduino Ethernet R2 82.28 78.75 ok ok

WIZ820io 330.30 183.69 ok ok

Seeed Ethernet W5500 328.14 179.98 ok ok

Arduino Uno Wifi Rev2 Arduino Ethernet R2 72.30 69.55 ok ok

Arduino Ethernet R3 72.23 69.50 ok ok

WIZ820io 212.19 161.94 ok ok

Arduino.org Ethernet2 212.88 169.72 ok ok (linkstatus wrong)

Seeed Ethernet W5500 213.36 163.86 ok ok (linkstatus wrong)

Arduino Mega 2560 Arduino Ethernet R2 77.44 74.31 ok ok

WIZ820io 325.44 172.73 ok ok

Seeed Ethernet W5500 323.36 179.58 ok ok

Arduino Zero Arduino Ethernet R2 96.64 91.42 ok ok

Arduino Ethernet R3 96.64 91.33 ok ok

WIZ820io 298.53 177.53 ok ok

Arduino.org Ethernet2 305.28 181.60 ok ok

Seeed Ethernet W5500 305.26 183.13 ok ok

Arduino Due Arduino Ethernet R3 109.73 105.98 ok ok

WIZ820io 670.88 206.51 ok ok

Seeed Ethernet W5500 689.69 214.44 ok ok

Arduino 101 (Intel) Arduino Ethernet R3 43.60 42.39 ok ok

WIZ820io 349.35 169.37 ok ok

Seeed Ethernet W5500 359.32 168.96 ok ok

Arduino MKR1000 MRK ETH 298.93 181.27 ok ok

WIZ820io 291.98 125.20 ok ok

Teensy 3.6 WIZ850io 1143.58 212.59 ok ok

WIZ820io 1102.71 202.44 ok ok

WIZ812MJ 274.14 180.76 ok ok

Teensy 3.2 WIZ850io 958.06 205.37 ok ok

WIZ820io 914.78 215.44 ok ok

WIZ812MJ 234.55 170.07 ok ok

Teensy LC WIZ850io 479.73 200.51 ok ok

WIZ820io 471.95 199.62 ok ok

WIZ812MJ 137.77 126.40 ok ok

Teensy 2.0 WIZ812MJ 84.85 81.07 ok ok

ChipKit Uno32 Arduino Ethernet R2 272.18 159.72 ok ok

WIZ820io 837.56 188.31 ok ok

Seeed Ethernet W5500 858.81 177.19 ok ok

Adafruit ESP8266 FeatherWing Ethernet 583.31 fail (dns) fail (dns) ok

Adafruit ESP32 FeatherWing Ethernet 965.76 211.06 ok ok

Possible issues:

Adafruit ESP8266 fails WebClient (google) and UdpNtpClient tests, due to DNS

Arduino Uno R3 with WIZ820io running WebClient sometimes fails to connect to google

Arduino Due with WIZ820io running WebClient sometimes fails to connect to google

Arduino Uno Wifi Rev2 with WIZ820io running WebClient sometimes fails to connect to google

Arduino Mega 2560 with WIZ820io running WebClient sometimes fails to connect to google

Near-Term Plans

Not everything I wanted to accomplish made the 2.0.0 release. These are changes I would like to make “soon”…

DNS on ESP8266 appears to be broken. Help wanted! Hopefully someone from the ESP community can look at this. Or at least point me to a board that uploads faster and has a working Ethernet shield! (nearly all ESP boards in Arduino form factor lack the 6 pin SPI header)

Non-blocking DHCP & DNS are needed for projects needing to keep rapid polling of other I/O.

DHCP could use improvements: set hostname, better handling of error conditions, disable when settings overridden by manual settings.

Farther Future Plans

In the distant future (and a dream world where I have many more hours in every day), I’d like to do much more with Ethernet.

Small writes could be combined and sent as single packets, if we had a timeout infrastructure or scheduler available.

DNS probably should migrate to Arduino core library, so it can shared among different networking libraries.

DNS cache should be implemented, at least with 1 entry, so we don’t repetitively look up the same host’s IP number.

Wiznet chips have an interrupt pin, which is currently unused. On high-end boards, we could allocated buffers in RAM and read data earlier, to allow faster TCP speeds over high latency networks.

Someday I’d love to integrate EventResponder…

But here & now, this 2.0.0 brings a much-needed features and a huge improvement in performance to all Arduino users!